How to Minimize Dust When Sanding the Body Filler?

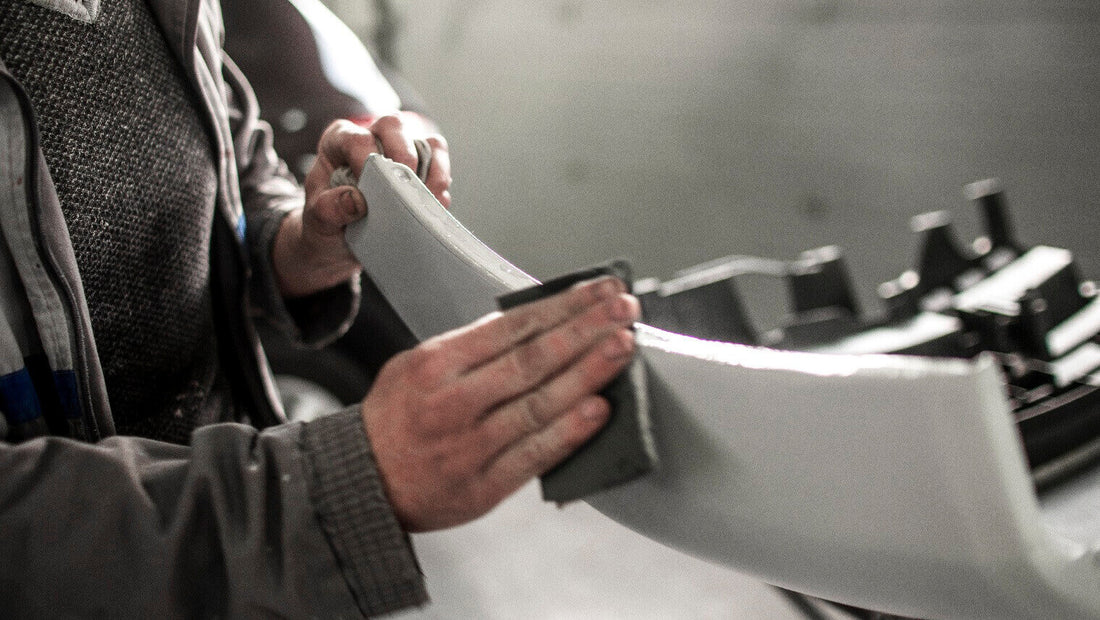

Body filler is typically applied to damaged or uneven areas of a vehicle's body, and once it hardens, sanding ensures that the repair area blends seamlessly with the surrounding surface. Achieving a flawless finish requires precision and the right techniques, making sanding a critical part of the process.

However, one of the most common issues during body filler sanding is the generation of excessive dust. This dust not only makes the workspace messy and difficult to maintain but can also pose significant health risks. In this guide, the team at Fastplus Abrasives will provide practical tips and effective techniques for minimizing dust while sanding body filler.

Understanding the Problem of Dust When Sanding Body Filler

Sanding body filler in automotive repair creates fine dust that can quickly become a major issue. This dust is not just a nuisance—it poses significant health risks and affects work efficiency. Body fillers often contain harmful chemicals like silica, which, when inhaled over time, can lead to respiratory issues, including lung diseases like silicosis. These fine particles can linger in the air long after sanding is done, posing continuous risks to those working in the area.

In addition to health concerns, dust can heavily impact the workspace. Excessive dust buildup reduces visibility, making it harder to achieve precision in sanding. It can also settle on other surfaces, including those being prepped for painting, leading to imperfections in the final finish. Maintaining a clean, dust-free environment is essential for both safety and delivering high-quality results in automotive sanding tasks.

Choosing the Right Sandpaper to Minimize Dust

When it comes to minimizing dust while sanding body filler, selecting the right sandpaper plays a crucial role. Various types of sandpaper are designed specifically to reduce dust production while maintaining high performance. Here, Fastplus Abrasives recommend three highly effective types of sandpaper: Netmesh sandpaper, Wet dry sandpaper, and Ceramic multi-hole sanding discs. Each of these options offers distinct advantages in terms of dust control and overall performance during body filler sanding.

1. Net CeraMesh Sanding Discs

Net CeraMesh Sanding Discs are engineered with an open-weave structure, allowing dust particles to pass through the mesh and be easily collected by dust extraction systems. This design helps reduce airborne dust significantly, keeping the workspace cleaner and safer. The open structure also prevents clogging, ensuring that the sandpaper maintains its cutting power for longer periods.

Advantages:

- Superior Dust Extraction: The mesh design allows for maximum airflow, improving the efficiency of dust collection.

- Clog-Resistance: By allowing dust to escape, Netmesh sandpaper maintains consistent sanding performance, extending the lifespan of the abrasive.

- Versatility: Suitable for both dry and wet sanding applications, making it an excellent choice for reducing dust in multiple settings.

Wet dry sandpaper is a dual-purpose abrasive that can be used for both dry sanding and wet sanding. When used with water, wet sanding dramatically reduces the amount of dust generated, as the water traps dust particles, preventing them from becoming airborne. Wet sanding also produces a smoother finish, making it ideal for final smoothing of body filler surfaces.

Advantages:

- Effective Dust Control: Wet sanding virtually eliminates airborne dust by containing it in the water.

- Smooth Finish: Using water helps lubricate the surface, resulting in a finer finish and less risk of clogging the sandpaper.

- Multi-Functional: This sandpaper can switch between wet and dry sanding depending on the needs of the project, offering flexibility in dust management.

Ceramic multi-hole sanding discs are designed with multiple holes to enhance dust extraction. The ceramic abrasive is known for its durability and high performance, allowing it to cut through tough materials like body filler with ease. The multi-hole design ensures that dust is channeled through the holes and effectively collected by a vacuum system, minimizing dust in the workspace.

Advantages:

- Enhanced Dust Collection: The multi-hole pattern increases dust extraction efficiency when paired with a dust collection system, reducing dust exposure.

- Durability: Ceramic abrasives are extremely tough, lasting longer and maintaining cutting power, which reduces the need for frequent replacements.

- High Performance: These discs offer fast material removal, ensuring efficient sanding with minimal dust production when used with a dust extraction setup.

Preparation and Workspace

A well-organized and clean workspace is essential when sanding body filler to minimize dust and maintain safety. Here’s how proper preparation can make a significant difference:

Maintain a Clean and Well-Ventilated Workspace:

A clean workspace reduces the amount of dust that settles on surfaces, preventing it from contaminating freshly sanded areas.

Proper ventilation helps disperse any airborne dust particles, reducing the risk of inhaling harmful dust from body filler.

Ensure that windows and doors are open, or use ventilation systems to keep fresh air circulating during the sanding process.

Use of Dust Extraction Systems or Fans:

- Dust Extraction Systems: Attaching your sander to a dust extraction system is one of the most effective ways to reduce dust during sanding. These systems pull dust away from the surface and contain it before it can become airborne.

- Fans for Air Circulation: In the absence of a dust extraction system, strategically placed fans can help redirect dust particles away from the work area, improving air quality.

- Portable Dust Collectors: Small, portable dust collectors can be placed near your sanding area to capture dust, keeping the workspace cleaner.

Sanding Techniques

Effective sanding techniques are crucial for minimizing dust and achieving a smooth, high-quality finish on body filler. Here’s a detailed guide to ensure optimal results while keeping dust to a minimum:

Use a Light Touch and Avoid Excessive Pressure:

- Controlled Pressure: Applying too much pressure can force the sandpaper to clog quickly and create more dust. Use a light, even touch to allow the sandpaper to do the work, ensuring a smoother sanding process.

- Consistent Application: Let the sandpaper glide over the surface without pressing too hard. This approach helps reduce the generation of excess dust and prevents uneven sanding.

Keep the Sandpaper Moving to Prevent Clogging:

Move the sandpaper continuously across the surface to prevent it from clogging with dust. This helps maintain the sandpaper’s effectiveness and minimizes the amount of dust produced.

If you notice the sandpaper starting to clog, clean it regularly by tapping it or using a sandpaper cleaning block to remove accumulated dust. This will keep the sandpaper efficient and reduce dust buildup.

Use a Sanding Block for a More Even Finish:

A sanding block helps distribute pressure evenly across the sanding surface, resulting in a more uniform finish. It also prevents the sandpaper from conforming to irregularities in the surface, which can cause uneven sanding.

Attach the sandpaper to the sanding block securely and use consistent strokes to ensure an even sanding action. This technique helps achieve a smoother finish and reduces the likelihood of creating dust hotspots.

Dust Containment Methods

Effective dust containment is essential for maintaining a clean and safe workspace during sanding. Here are several methods to help manage and minimize dust effectively:

Using a Sanding Booth or Tent:

- Sanding Booth: A dedicated sanding booth is designed to contain dust within a controlled environment. It often includes built-in ventilation systems that capture and filter dust, ensuring that it doesn’t spread into the surrounding area.

- Sanding Tent: A more portable option, a sanding tent can be set up around your work area to contain dust. These tents are equipped with mesh panels and sometimes include filtration systems to trap dust and prevent it from escaping.

Using a Portable Dust Collector:

Portable dust collectors are designed to capture dust directly from the sanding process. They are usually equipped with a hose that attaches to the sander, pulling dust away from the surface and into a collection bag or container.

By using a portable dust collector, you can significantly reduce airborne dust and keep your workspace cleaner. These units are particularly useful in smaller workshops or for mobile repair work.

Placing a Wet Cloth or Sponge Under the Sanding Area:

Placing a wet cloth or sponge under the sanding area helps trap dust particles before they can become airborne. The moisture from the cloth or sponge captures dust, preventing it from spreading throughout the workspace.

Achieve Cleaner, Safer Sanding with Fastplus Abrasives' Solutions

Achieving a dust-free environment during body filler sanding is essential for both health and quality results. At Fastplus Abrasives, we offer advanced sanding solutions, including netmesh sandpaper, wet dry sandpaper, and ceramic multi-hole sanding discs, designed to significantly reduce dust and enhance your sanding experience. For optimal results, combine these abrasives with effective dust extraction systems and proper workspace preparation. Trust Fastplus Abrasives to help you maintain a cleaner, safer, and more efficient working environment.