How Sandpapers Enhance Efficiency in Aerospace Manufacturing?

Aerospace manufacturing involves the complex process of designing, fabricating, assembling, and testing aircraft and spacecraft components. From the construction of airframes to the integration of avionics systems, every step in aerospace manufacturing plays a crucial role in delivering reliable and efficient aircraft and spacecraft.

As abrasive tools, sandpapers are instrumental in shaping, smoothing, and refining the surfaces of aerospace components to exact specifications. Whether preparing surfaces for bonding, removing imperfections, or achieving precise finishes, sandpapers offer versatility and precision in machining operations. In this blog, we will explore the diverse applications of sandpapers in aerospace manufacturing and uncover how they maximize efficiency and performance in this industry.

The Importance of Surface Preparation in Aerospace Manufacturing

Surface preparation is a critical aspect of aerospace manufacturing, playing a pivotal role in ensuring the integrity, reliability, and performance of aircraft and spacecraft components.

Proper surface preparation is essential for several reasons:

- Bonding: Surfaces must be clean and free from contaminants to facilitate strong and durable bonds between components. Any residues or impurities on surfaces can compromise the adhesion of bonding agents, leading to structural weaknesses and potential failures.

- Corrosion Protection: Aerospace vehicles operate in harsh environments, including exposure to moisture, salt, and chemicals. Effective surface preparation, such as cleaning and coating, helps protect components from corrosion and degradation, prolonging their lifespan and ensuring operational safety.

- Paint Adhesion: For aesthetic purposes and corrosion resistance, aerospace components often require painting. Proper surface preparation, including cleaning, sanding, and priming, promotes optimal paint adhesion, ensuring a durable and uniform finish.

- Machining and Assembly: Machined surfaces must be smooth and uniform to meet precise dimensional tolerances and facilitate assembly. Surface preparation techniques, such as sanding and deburring, help remove imperfections and ensure proper fitment of components during assembly.

Sandpapers in Action: Enhancing Efficiency

Surface Preparation:

Sandpapers are indispensable tools in aerospace manufacturing for preparing surfaces for various processes, such as bonding, painting, and machining. Surface preparation is a critical step that ensures the integrity, adhesion, and quality of subsequent manufacturing operations. Sandpapers are utilized to remove contaminants, rough spots, and oxidation from surfaces, creating a clean and uniform substrate for bonding adhesives, primers, or coatings. By effectively removing surface imperfections, sandpapers improve the efficiency of bonding and painting processes, reducing the likelihood of adhesion failures or surface defects. Moreover, sandpapers facilitate machining operations by smoothing surfaces and ensuring dimensional accuracy, enhancing the efficiency and precision of subsequent manufacturing steps.

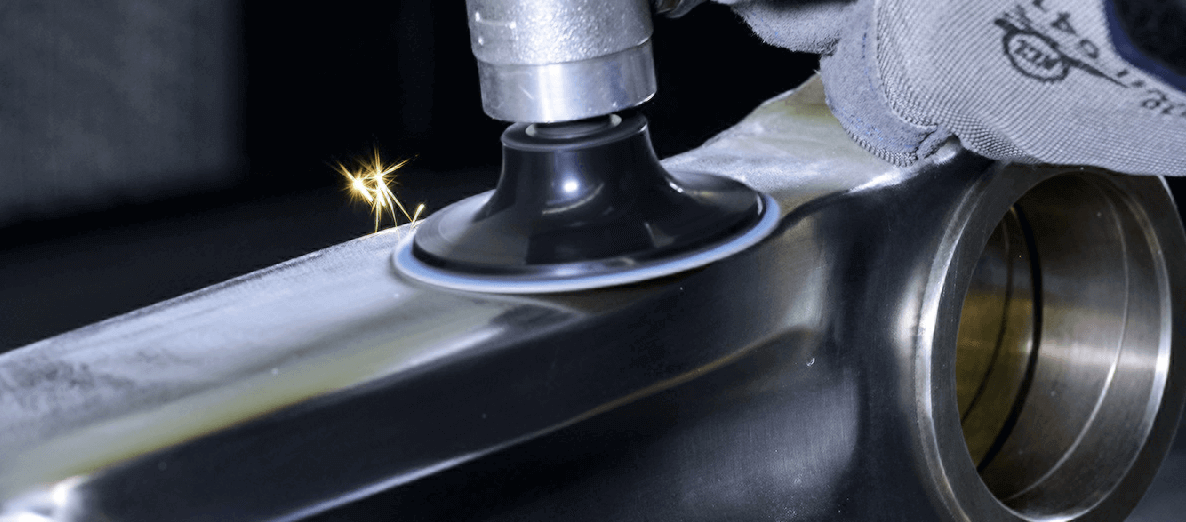

Deburring and Finishing:

Another key application of sandpapers in aerospace manufacturing is deburring, the process of removing sharp edges and burrs from machined or stamped components. Sandpapers with appropriate grit sizes and abrasive properties are used to smooth out these imperfections, ensuring that components fit together seamlessly during assembly. Additionally, sandpapers are employed to achieve specific surface finishes required for different aerospace components. Whether it's a smooth, mirror-like finish for aerodynamic surfaces or a textured finish for better paint adhesion, sandpapers enable manufacturers to achieve the desired surface characteristics efficiently. By reducing the need for manual finishing and rework, sandpapers contribute to faster assembly times and improved product quality, ultimately enhancing efficiency in aerospace manufacturing.

Tooling and Mold Maintenance:

In aerospace manufacturing, tools and molds are subjected to rigorous use and wear, necessitating regular maintenance to ensure optimal performance and longevity. Sandpapers play a crucial role in maintaining and cleaning these critical assets. They are used to remove residues, corrosion, and surface imperfections from tooling and molds, restoring them to their original condition. By keeping tools and molds in top shape, sandpapers help minimize downtime associated with replacements or repairs, thereby maximizing operational efficiency and reducing production costs.

Composite Manufacturing:

Composite materials, exemplified by carbon fiber reinforced polymers (CFRP) and fiberglass, stand as the cornerstone of modern aerospace innovation, owing to their unparalleled blend of lightweight agility and formidable strength. Within this realm of cutting-edge fabrication, sandpapers emerge as unsung heroes, wielding a transformative influence on the production process. Crafted with meticulous precision, specialized sandpapers, including those endowed with diamond or ceramic abrasives, are the artisan's tools of choice, sculpting and refining composite surfaces with unparalleled finesse. By orchestrating a delicate dance between efficiency and precision, these abrasives not only minimize the risk of delamination and fiber damage but also elevate the aesthetic and functional integrity of the final product. In the grand tapestry of aerospace engineering, the role of sandpapers transcends mere functionality; it is the silent force propelling the industry towards new heights of performance and efficiency.

Types of Sandpapers Used in Aerospace Manufacturing

Sandpapers utilized in aerospace manufacturing come in a diverse array of types, each meticulously designed to suit specific materials, applications, and surface finish prerequisites. Grasping the nuances and benefits of various sandpaper types is imperative for attaining peak performance in aerospace manufacturing endeavors.

Among the myriad options available, several common types stand out:

Silicon Carbide Sandpapers:

Silicon carbide sandpapers are preferred for their aggressive cutting action and ability to produce smooth finishes on hard materials. They are commonly used in aerospace manufacturing for sanding tough materials such as titanium and advanced alloys. Silicon carbide abrasives are also resistant to heat and wear, making them suitable for demanding machining operations.

Ceramic Sandpapers:

Ceramic sandpapers feature advanced ceramic abrasives that offer exceptional durability and cutting performance. They are specifically designed for heavy-duty material removal and shaping tasks in aerospace manufacturing. Ceramic abrasives are highly wear-resistant and maintain sharpness over extended use, making them ideal for grinding and leveling surfaces in aerospace components.

Aluminum Oxide Sandpapers:

Aluminum oxide sandpapers are versatile and widely used in aerospace manufacturing for their durability and versatility. They are suitable for sanding a variety of materials, including metals, composites, and plastics. Aluminum oxide abrasives offer excellent cutting power and heat resistance, making them ideal for shaping and smoothing surfaces in high-temperature applications.

Diamond Sandpapers:

Diamond sandpapers utilize industrial-grade diamond abrasives for precise and efficient material removal in aerospace manufacturing. They are particularly suited for machining and finishing hard materials such as carbon fiber composites and ceramic matrix composites. Diamond abrasives provide superior cutting power and long-lasting performance, enabling manufacturers to achieve precise surface finishes and dimensional accuracy.

Film-backed Sandpapers:

Film-backed sandpapers feature a durable and flexible film backing that provides excellent tear resistance and conformability. They are ideal for sanding contoured surfaces and intricate shapes in aerospace manufacturing. Film-backed sandpapers offer consistent performance and durability, making them suitable for high-precision finishing applications in aerospace components.

Wet/Dry Sandpapers:

Wet/dry sandpapers are versatile options that can be used with or without water or lubricants, depending on the application requirements. They are suitable for both wet and dry sanding operations in aerospace manufacturing, offering flexibility and convenience. Wet/dry sandpapers are commonly used for surface preparation, deburring, and finishing tasks in aerospace component fabrication.

Conclusion

Sandpapers stand as indispensable assets in aerospace manufacturing, fostering efficiency and precision across various stages of production. From surface preparation to deburring and finishing, these abrasive tools play a pivotal role in ensuring the integrity, reliability, and performance of aircraft and spacecraft components. Their versatile nature and precise capabilities make them indispensable companions in the pursuit of aerospace innovation and excellence.