How to Select the Right Sanding Discs?

Sanding discs are circular abrasive discs that remove material, light defects, corrosion, paint, and rust from wood, metal, and plastic surfaces. They attach to disc sanders, angle grinders, or handheld rotary tools, and they allow for good control of a workpiece, as workers can see the workpiece at all times when sanding discs are in use. Coarse grit removes material such as welds on metal or mill marks on wood, while fine grit buffs out tool marks and evens out edges. Adhesive-backed and hook-and-loop discs allow for quick switchouts of sanding discs. Industrial sanding disc rolls keep fresh discs on hand in applications requiring heavy or frequent sanding, such as in woodshops and production facilities.

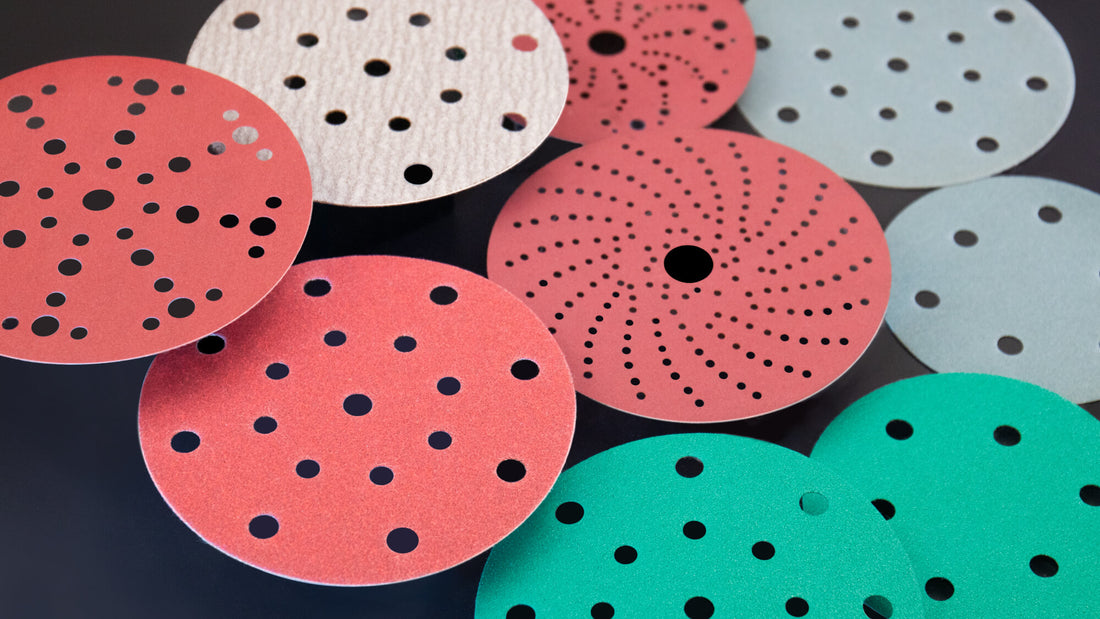

Features of Abrasive Discs

Abrasive discs also differ in terms of mounting and special features. For example, hook and loop mounting attaches the abrasive using a hook and loop fabric whereas bore or center mounting use a central hole through which the disc attaches to the integral mandrel, arbor, spindle, or shaft. Other types of mounting include quick change and PSA/adhesive. In terms of features, abrasive discs may use an open or closed coat, metal bond, or disc roll. DeLappe and flutter discs have a series of radially cut shifts emanating from the center or around the disc periphery.

Abrasive discs consist of abrasive grains adhered onto a backing of:

- cloth

- fiber

- film

- paper

- non-woven

- other material

What Are the Abrasive Types of Sanding Discs?

Aluminum oxide is a popular abrasive, known for its hardness and strength and low cost when compared to other abrasive types. It has low heat retention and low specific heat making it useful in a wide array of grinding and sanding applications. Aluminum oxide occurs naturally in the form of the mineral corundum, but the mineral is not used as a commercial abrasive except as a component of emery. When combined with emery and/or crocus, it produces an abrasive suitable for finishing applications.

Aluminum oxide is often fused with chemical additions to titanium oxide or chromium oxide to enhance its abrasive uses. The various types of fused aluminum oxides are distinguished by the levels of chemical impurities remaining in the fused mineral. Titanium oxide additions can toughen the abrasive and enable further performance enhancement by grain heat treating processes. Calcined or platelet aluminas as used in fine grit or polishing applications. While most sol-gel abrasives are aluminum based, these alumina abrasives are classified as ceramic abrasives. Ceramic abrasives represent the next generation of abrasives. They are becoming popular in metalworking applications because they grind cooler and faster compared to fused aluminum oxides. Due to its specialized crystalline structure, sol-gel abrasives "self-sharpen" allowing for a long functional lifespan.

Silicon carbide (SiC) is a widely used abrasive due to its durability and low cost. It is a synthetic abrasive first developed in the late 1800s. SiC is harder than aluminum oxide, but more friable than fused aluminum oxide grains. Since silicon and carbon are both soluble in steel, silicon carbide is not a effective in grinding steel or ferrous alloys—especially with coarser grit sizes in heavy metal removal applications. Silicon carbide is typically used in applications involving nonferrous metals such as brass, aluminum, and titanium, and for abrading non-metals such as stone, glass, wood, and leather.

Superabrasive disc types include diamond and cubic boron nitride (CBN). Superabrasive diamonds have the highest known hardness of all abrasive grains. They are used for grinding and sanding nonferrous metals, ceramics, glass, stone, and building materials. Diamond abrasive discs are not useful in grinding steel or ferrous alloys because the carbon in diamond readily dissolves or reacts with iron. However, diamond pastes are useful in ferrous polishing or lapping applications where heat and reactivity are not a factor. When working with ferrous metals, CBN is a better choice. Cubic boron nitride is not as hard as diamond.

Other types of grains include ceramics, garnet, tungsten carbide, and alumina-zirconia abrasives.

What are the Backing Materials of Abrasive Discs?

Abrasive discs are constructed using one (or more) types of backing. Backings are the flexible material to which abrasive grain is adhered to make coated abrasives and similar products. Typical backing materials include cloth, fiber, film, foam, sponge, and metal. Cloth discs consist of woven fabric such as cotton and are used in aggressive applications such as abrasive planing. Fiber discs are denser than cloth and contain vulcanized or chemically treated cotton or cellulose fibers; however, fiber discs may curl under humid conditions. Film discs use abrasive grains on plastic film, while foam and sponge discs use abrasive grains bonded onto a foam layer, sponge, felt, or other soft, resilient materials. Similarly, metal discs use abrasive grains bonded onto a metal backing such as aluminum or brass. Other types of disc backing include paper, screen, non-woven, or aggregate materials.

What is A Sanding Disc Used for?

These units are then mounted on a sander, grinder, or similar tool and used in a variety of sanding, grinding, polishing, and surface preparation applications. One of the most common uses of abrasive discs is in sanding applications. Such discs remove surface materials such as metal, ceramics, glass, plastics, and paint, as well as burrs and other imperfections. Depending on their construction, non-woven surface conditioning discs can be used in wet and dry grinding, sanding, cleaning, polishing, and surface preparation applications in a variety of industries, including metalworking, woodworking, ceramics, and even semiconductor manufacturing.

Buy Fastplus Factory-Direct Abrasives

Want to purchase high-quality, factory-direct sanding discs, sanding sheet rolls, and film abrasive discs for automotive applications? Try Fastplus Abrasives today and place your orders online!